Project Info

Project Description

Location: Rockdale, NSW

Project Type: Commercial Facility

Challenge: Mitigating Vapor Intrusion and Ensuring Air Quality on a Contaminated Site

Overview:

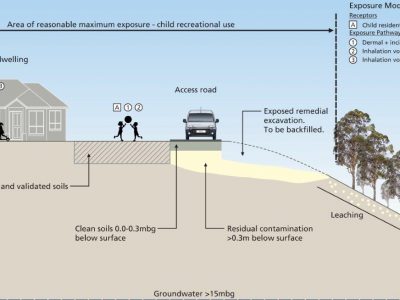

Our client required an advanced subslab ventilation system for a new commercial facility. The challenge was to design a system that would effectively manage subsurface vapor intrusion, ensuring a safe and healthy environment for future occupants.

Solution:

- Comprehensive Site Assessment:

We began with a detailed assessment of the site, focusing on the potential risks associated with trichloroethylene (TCE) and other contaminants. Using state-of-the-art vapor modelling techniques, we identified key areas where vapor intrusion could pose a risk. - Custom System Design:

Our engineering team developed a customized ventilation solution tailored to the unique needs of the site. The design included:

- Vapor-Resistant Membrane: Installed beneath the slab to prevent vapor intrusion.

- Sub-Slab Ventilation System: Featuring strategically placed ventilation pipes connected to wind-driven exhaust turbines, ensuring continuous extraction of vapours.

- Advanced Air Quality Monitoring: Integrated sensors to monitor air quality and system performance in real-time.

- Seamless Installation:

Our expert technicians installed the system with precision, ensuring all components were perfectly aligned and functional. The use of high-quality materials guaranteed long-term durability and efficiency. - Rigorous Testing and Validation:

Post-installation, the system underwent extensive testing to confirm it met all design specifications. This included checking the effectiveness of the vapor barrier and ensuring the ventilation system maintained optimal airflow rates. - Compliance and Long-Term Maintenance:

The entire project was executed in full compliance with NSW EPA guidelines. We also provided the client with a detailed maintenance plan to ensure the system continues to perform at peak efficiency for years to come.

Outcome:

The ventilation system successfully mitigated vapor intrusion, providing a safe environment for the facility’s future operations. Our client was able to proceed with the development, confident that the system would maintain indoor air quality and comply with all regulatory standards.

This case study highlights our commitment to delivering tailored, high-performance solutions that address complex environmental challenges.